Subfloors for Engineered Wood Flooring

A suitable, solid subfloor is a vital part of creating long-lasting high-quality flooring. And the type of subfloor you have will affect which product you can choose and the way it can be installed. So, what type of subfloor will work underneath wood flooring?

Let’s look at the 4 most common types of subfloor below:

- Concrete or Screed

- Wooden Joists

- Chipboard or Plywood

- Existing Floorboards

Concrete or Screed:

Screeds are used in conjunction with concrete to achieve a very smooth, hard surface on the ground floors of domestic properties. Concrete slabs and screeds are made up of the same material; concrete is simply stronger and coarser than screed.

The quality and condition of concrete and screed subfloors will vary. You might need to carry out some preliminary work to prepare the subfloor for your wood flooring. If you’re unsure, we advise getting an experienced professional floor fitter to check it over.

Before you can install wood flooring your subfloor must be clean, dry, flat, and level.

Excess moisture in your subfloor will likely damage your wood flooring, so it is vital to ensure the concrete or screed is completely dry. Always use a hygrometer to check the moisture level of a concrete or screed subfloor prior to fitting. You may find it requires some extra drying time or the installation of a damp proof membrane (DPM).

If you’ve got an old, damaged, or uneven concrete slab, you can use a self-levelling compound to create a flat, level surface. And the subfloor should be free of any contaminants such as sealers, paints, or anything that may hinder the adhesive’s ability to secure the flooring.

In terms of flooring installation methods, you can either fully bond wood flooring to a screed (recommended) or float your planks over an underlay.

Wooden Joists

Joists are structural timbers which span two walls or beams as a supporting framework for your flooring. To fit wood flooring directly to joists, you’ll need planks that are thick enough to provide the required load bearing strength, such as our 20mm thick Bristol Tectonic® planks.

Fitting wood flooring to joists involves securing them by ‘secret’ screwing or nailing your planks at an angle through their tongues. Your boards should be fixed to every joist. Depending on the property’s age and the building regulations in place at the time it was built, joists are generally spaced between 350mm and 600mm apart.

Fix your planks at least 75mm from the end of the board. Our 20mm Bristol Tectonic® planks are end-matched, with a tongue and groove on the ends of the boards. This allows you to join them between joists.

The direction which these joists are running will determine the orientation of your planks, so this may affect your choice.

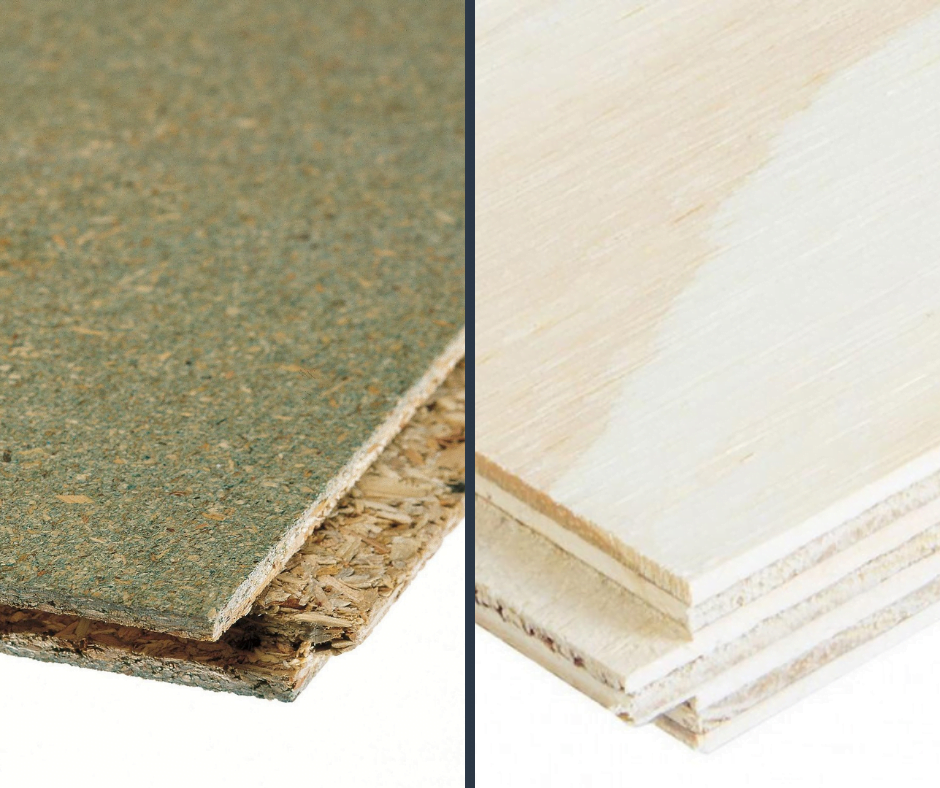

Chipboard or Plywood

Subfloors made of chipboard and plywood are commonly installed over floor joists. High-quality chipboard or plywood sheets can make an ideal subfloor for wood flooring installations.

We advise fully bonding your wood flooring if you have a chipboard subfloor. Plywood is a very versatile option which allows for a wide variety of flooring products and fitting methods; wood flooring can be can fully bonded (recommended), secret screwed, or floated on a plywood subfloor.

If you’re fixing chipboard or plywood over your joists, bear it mind that it must be thick enough for load bearing applications i.e., usually 18mm for plywood, 22mm for chipboard. For minimum depth allowed, consult your Local Authority Building Regulations.

Chipboard, also referred to as Caberfloor, is cheaper but not as robust or versatile as ply. It doesn’t hold fixings as firmly as plywood and even moisture resistant P5 chipboard doesn’t cope with moisture as well. It’s worth noting that not all plywood is created equal; different grades are available based on both their appearance and intended purpose — from standard interior ply to ‘marine grade’ ply.

When installing a new subfloor for engineered wood flooring, we recommend plywood instead of chipboard. Ply is generally more durable, stronger and will create the most reliable subfloor for your flooring. High-quality tongue and grooved plywood is your best option, and we always recommend exterior grade ply subfloors for kitchens and bathrooms.

Existing Floorboards

You might have a subfloor consisting of old floorboards, which will usually be a softwood floor such as pine. A new hardwood floor can either be secret nailed or screwed, or floated directly onto these boards. That said, it depends on the condition of the existing flooring.

When fitting directly onto existing floorboards, your new boards must be laid perpendicular to the old floorboards. This might look odd unless the room is square.

We advise fixing ply over existing boards if you don’t wish to remove them. This will usually overcome issues with undulation and allows you to fit your flooring in any direction and to fully bond it. Make sure any squeaky, unsecure floorboards are fixed prior to fitting onto them.

If the old floor is too uneven or damaged, you may need to either remove it and fix directly to the joists, or replace the floor with a plywood subfloor to create a viable fitting surface.

Any Questions?

If you have any questions about subfloor preparation for our Bristol Tectonic® engineered wood flooring, feel free to ask our friendly customer service team.