What Is the Ideal Moisture Content for Wood Flooring?

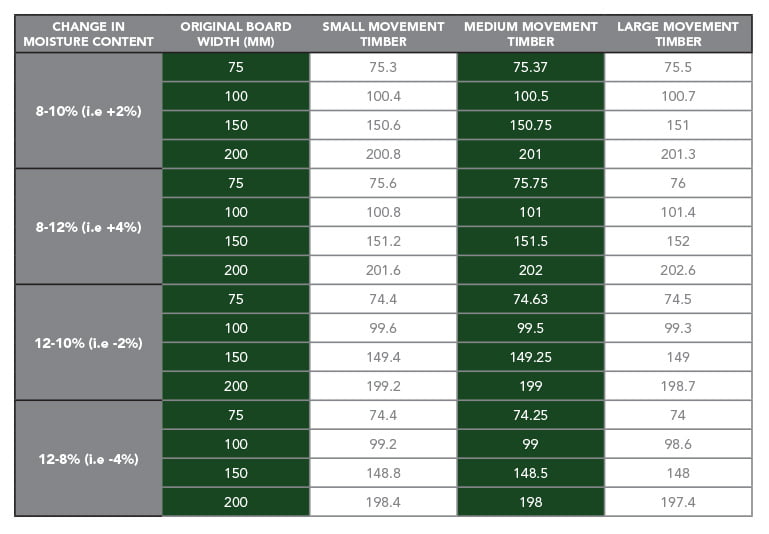

Wood is a hygroscopic material, meaning it is susceptible to holding and releasing water molecules via either absorption or adsorption. These changes in moisture content will cause the wood to swell or shrink; this is an entirely natural characteristic of hardwood flooring— it will always move. With the right precautions, the movement should be minimal and barely noticeable.

To understand how things can go wrong when installing wood flooring, it’s useful to have some knowledge of relative humidity and moisture content.

Humidity & Relative Humidity

Humidity simply means the amount of water vapour in the air, i.e. the air’s moisture content.

Relative humidity (RH) is the term used for the measurement of how much moisture is in the air relative to how much moisture the air will hold before it begins condensing into water. RH is a relative value of the amount of moisture needed to saturate the air at the current temperature.

RH for a given area may change depending on the ambient temperature and humidity. The colder the air is in a given area, the higher its RH value will be. Warmer areas will have a lower RH value. This is because it takes more moisture to reach the saturation point where it will condense into water.

A reading of between 40-65% RH would be expected in most homes. It will change along with the seasons, but it shouldn’t usually go far from this range.

Moisture Content of Wood

The moisture content of wood can be measured accurately with a moisture meter, known as a hygrometer.

Cupping, Crowning & Gaps in Wood Flooring

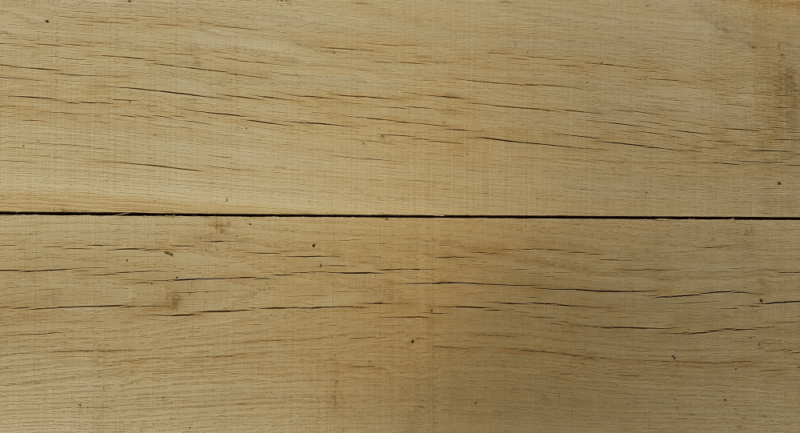

When the RH in a room goes up, wood absorbs moisture from the air; this increases the moisture content of the wood. The wood will expand when this happens. High levels of moisture in wood can lead to floorboards cupping or crowning as they swell. If unwanted moisture beneath the planks is absorbed, the boards will start cupping (left). When excess moisture is left on the top of the floorboards, they will start crowning (middle).

The wood loses moisture to the air when the RH goes down. This causes the wood to shrink. Too much shrinkage can lead to unwanted gaps between your floorboards (right).

Optimum Moisture Content for Wood Flooring

When it comes to creating a beautiful lasting wood floor, the aim is to keep the moisture content of the wood as stable as possible. The optimum moisture content for wood flooring in the UK is 8 – 11%. These levels are well-suited to most British homes.

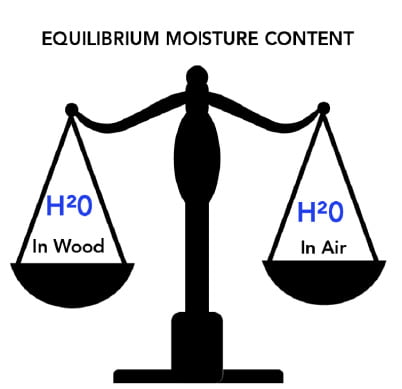

Equilibrium Moisture Content

The Equilibrium Moisture Content (EMC) is the moisture content level at which the wood is no longer gaining nor losing moisture. If we keep wood flooring at a consistent temperature and RH, it will eventually reach this point of equilibrium. When the wood has reached EMC, it means it has fully acclimatised and has reached a balance with its environment.

Wood’s Moisture Content Life Cycle

Your wood flooring has quite a story to tell; the changes it has been through will affect how it responds to becoming part of your home.

Unseasoned oak, known as Green Oak, has a moisture content of around 80%. In order to use this timber as flooring, we need to drastically reduce this. This means air drying or kiln drying the timber, or a combination of the two.

Air Drying or seasoning the oak is a lengthy process— and one that some suppliers forego due to the extra time involved— taking anywhere from 9 months to 2 years depending on the climate. This should reduce the moisture content down to around 20%. Seasoning the timber in this way makes it much more stable because the change in moisture content has been so gradual.

Kiln drying timber takes the moisture content down to around 10%. It dries the timber very quickly and can be ready to use in a matter of 2 or 3 weeks. However, if the mills don’t do it correctly it can cause stresses in the wood which damage its structure and cause instability.

Moisture Content of Chaunceys Wood Flooring

At Chaunceys, our suppliers season the timber for 9-12 months and then kiln-dry it. We then carefully store our boards at around 9% moisture content. We monitor and regularly record the moisture content of all of our timber and check again before sending it out to our customers. This way we know how it will respond to its new home.

Stacking & Acclimatisation

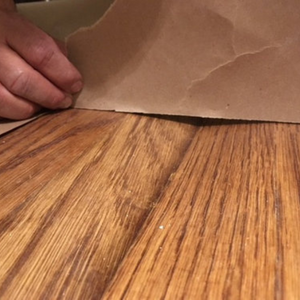

Getting your floor used to its new surroundings is essential. When it is delivered, it’s best to remove any wrapping and stack the boards on wooden battens to allow airflow around them. We advise acclimatising your wood for the recommended period (see below) in the room it’s going to be fitted in.

Engineered Boards

Although our engineered boards are extremely stable and cope very well with changes in RH, we recommend a minimum of 72 hours of acclimatisation before fitting.

New Solid Boards

Allow 10 to 14 days for solid wood boards to settle into their new home before laying.

Reclaimed Boards

Due to the nature of reclaimed timber, you should allow approximately 3 weeks for your reclaimed boards to become as stable as possible before installing them.

You can tell when the boards are fully acclimatised and ready to install by carrying out moisture checks of the boards on-site, as well as monitoring the temperature and RH of the property.

Moisture Content of the Subfloor

The moisture levels in the subfloor on which the boards are being laid must be thoroughly checked with a moisture meter too.

Where flooring is being bonded directly over a new screed floor, it is essential that the screed is completely dry before laying wood flooring on top of it— allow at least 1 month for every 1-inch depth of new concrete. If this is not possible, or moisture levels are too high, a suitable dampproof membrane must be installed. If wood flooring is installed on a subfloor which has excess moisture, it is likely to move and buckle, which will damage it.

Consistency is Key

The more consistent the temperature and RH in your home, the better. Cranking up your heating won’t speed things up in terms of acclimatisation, in fact doing this could cause issues with your floors later down the line; so just keep it set at a constant, comfortable temperature that you would typically have in your home.

We recommend for the property to have a temperature of 15-24°C, and RH of 40-65% for 14 days before installation, and to keep these conditions as consistent as possible during and after installation.