How is Wood Flooring Manufactured?

Creating a Chaunceys Oak Floorboard: From Tree to Plank

Most of our boards are made using European Oak. Chaunceys are FSC® (FSC-C131323) certified and we are careful to source our timber from managed forests and sustainable sources.

After the trees are harvested, the logs are selected for use as flooring based on their natural beauty. Sawmills select flooring timber with a tight grain and fewer knots than timber designated for other uses.

Sawing

Most commonly, sawmills will flat saw the logs (also known as plain sawing) into rough planks, ready to be made into wood flooring.

Sawmills sometimes use more expensive cutting methods such as quarter sawing. This is where sawmills cut the log into quarters before sawing. This is a more wasteful method, but it produces planks with a straighter grain. As a result, they are less susceptible to expanding, warping, and twisting. Quarter Sawn oak is also sought after due to the attractive flecks in the boards, known as medullary rays.

The most expensive flooring is rift sawn, where the log is carefully cut at specific angles to the tree’s annual growth rings. This creates the highest quality and most structurally stable planks.

Drying

To stabilise the timber for use as floorboards, our suppliers air dry then kiln dry it to a moisture content of around 10%. The drying process is a vital step in making high-end wood flooring. At Chaunceys we ensure any new wood we source has gone through this process.

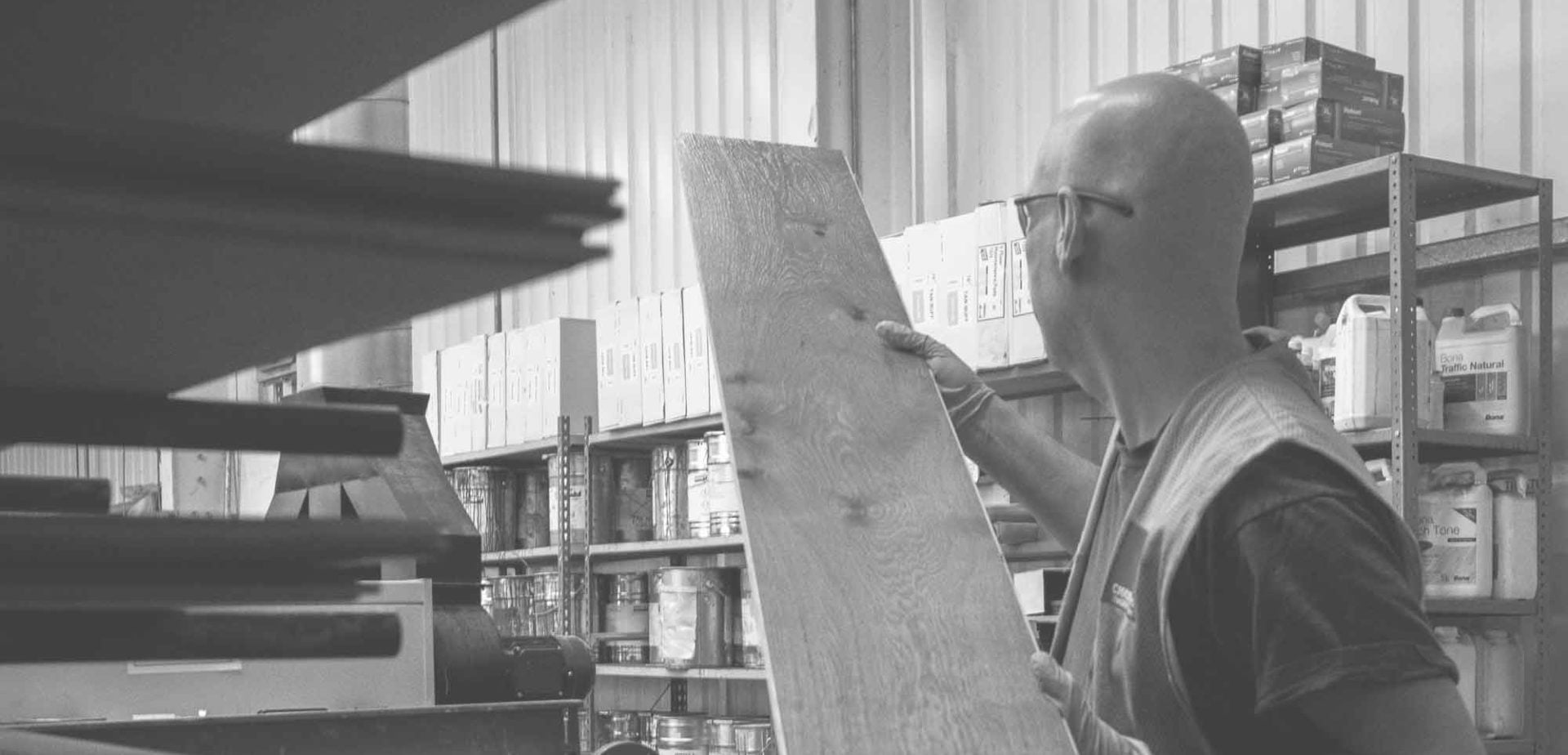

Quality Checking and Grading

Any knots are filled by hand and then sanded. Defects are removed during stringent quality control checks.

The planks are inspected, categorised, and divided into grades (e.g. Prime or Character) based on their appearance and the number of knots or imperfections present in the wood. Please see the Chaunceys’ grading guide for more information on the differences between each available grade.

How is a Chaunceys Bristol Tectonic® Engineered Board Made?

Using state-of-the-art production methods, our range of engineered wood flooring is made with a solid oak top layer which is bonded to a core board constructed of high-grade birch plywood.

At Chaunceys we offer a great range of board sizes to suit your needs, including extra-wide boards up to 300mm. Our extra long engineered boards look fantastic in larger rooms.

Top Layer

Sawmills dry saw our high-quality solid wood top layer from the original planks. Cutting the top layer in this way means that each board is completely unique, with no repeating grain patterns and all the natural beauty of solid hardwood flooring.

Core Board

To create an exceptional engineered floorboard, the production of a high-quality core board is a key step in the manufacturing process. The core board is made up of multiple layers of plywood stacked and glued on top of each other with the grains in alternating directions. These ply layers are then mechanically pressed.

At Chaunceys we source top-quality grade (B/BB) water-resistant birch plywood with no knots in the middle and top layers — this provides the strongest possible bond between each layer.

Pressing and Acclimatisation

The next step: our specialist manufacturers then glue and press the oak top layer to the ply core board using a hydraulic press. Afterwards, the top layer and core board are acclimatised together to ensure the boards are completely stable.

Machining and Sanding

Tongue and groove profiles are precisely machined into the boards; these allow the boards to fit together perfectly whilst letting them expand and contract without creating any gaps between the floorboards.

Then, the mill machine-cuts our micro bevel profile along the edges of the boards. Finally, each board is very accurately sanded to the exact dimensions required.

The boards are then ready to be finished by our team of experts. At Chaunceys, we offer a wide variety of tones, sheen levels and textures to meet the requirements of our customers.

If you have any questions about how our boards are made, or if there’s anything else you’d like to know about wood flooring, feel free to ask our friendly sales team — they are very knowledgeable and always happy to help.