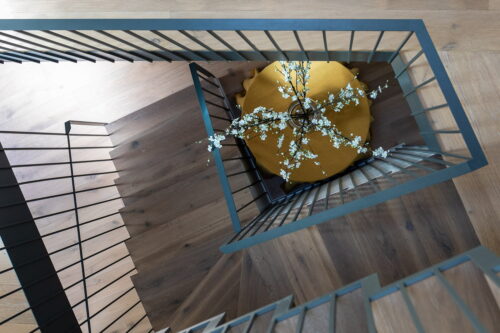

What’s the Difference Between Quarter Sawn Oak and Flat Sawn Oak?

Sawing Methods and Grain Patterns in Oak Flooring

Oak can provide a very attractive grain that displays a unique pattern — like a tree’s individual fingerprint — on each board. A lot of the visual interest of wood flooring comes from this beautiful variation of the wood’s grain, influenced by the natural arrangement, size, and direction of the wood’s cells, and from the way in which the boards are sawn. So, what is the difference between flat sawn oak and quarter sawn oak? And how does the sawing method affect the grain’s appearance?

Making the Cut: Timber Sawing Methods

Put simply, the wood grain refers to the appearance of varying wood fibres seen on the surface of cut wood. These grain patterns on the face of each board are dependent on the way that sawmills cut the oak logs. With that in mind, let’s explore the common sawing methods used when producing oak flooring, and how they affect the way it looks.

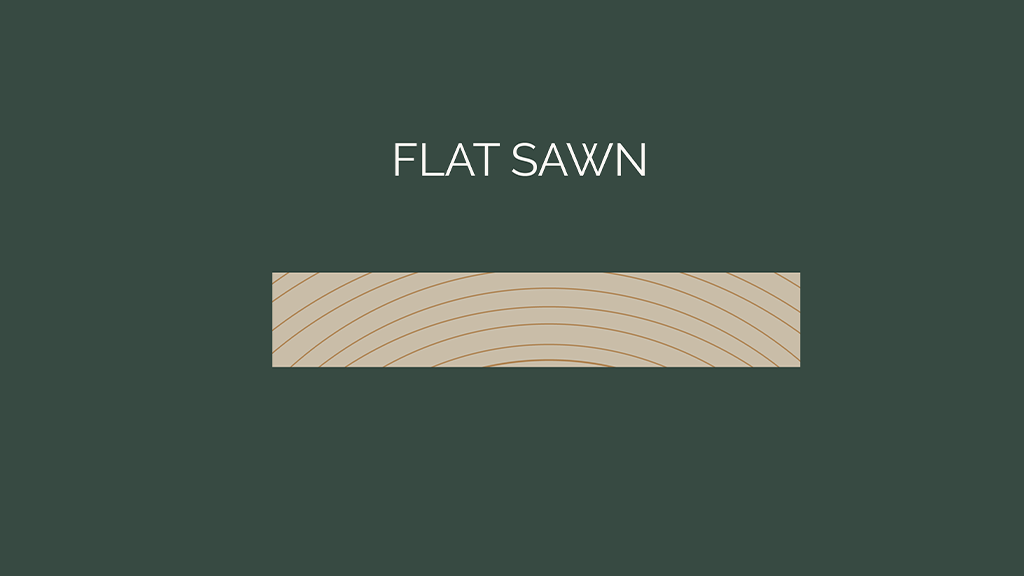

Flat Sawn Oak

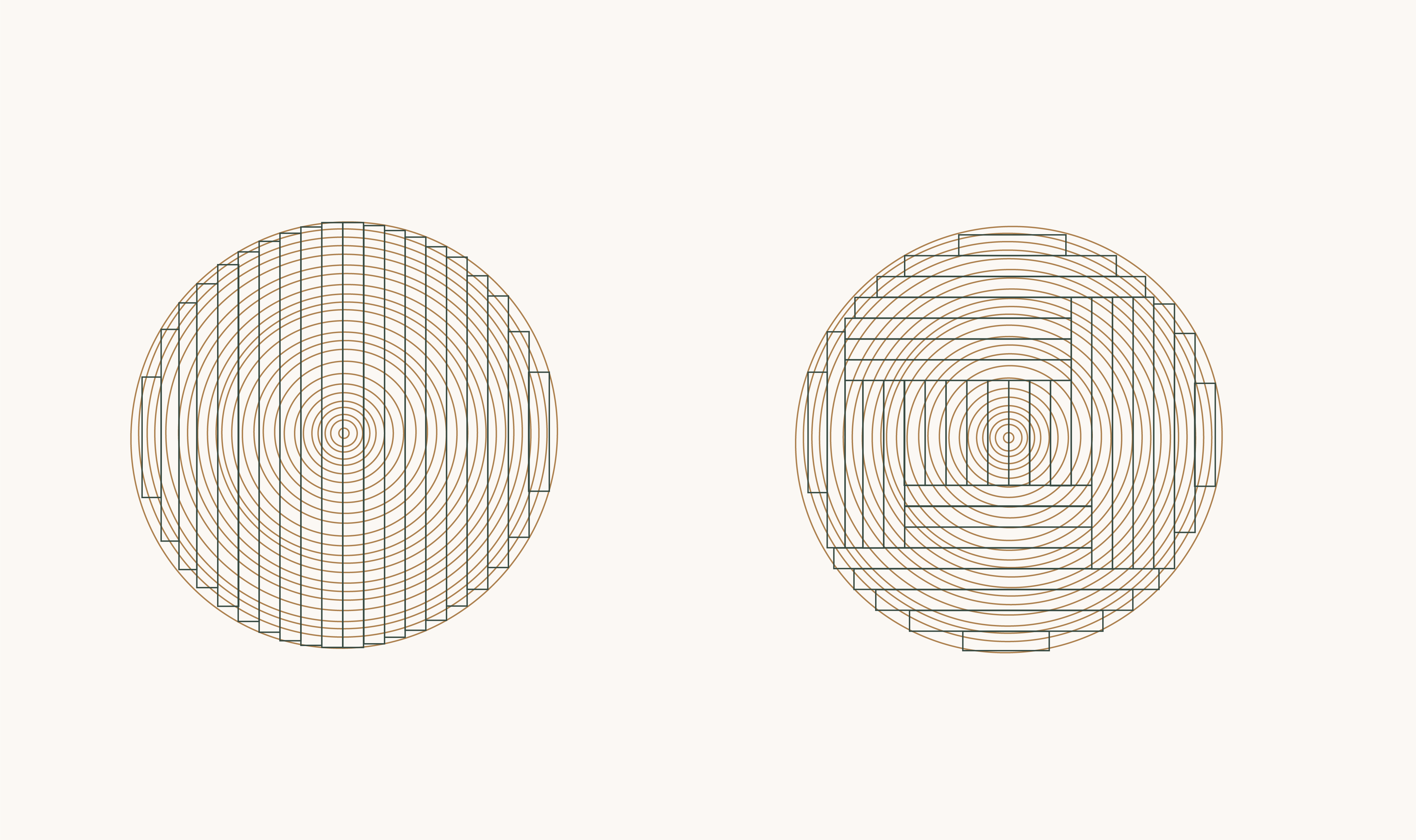

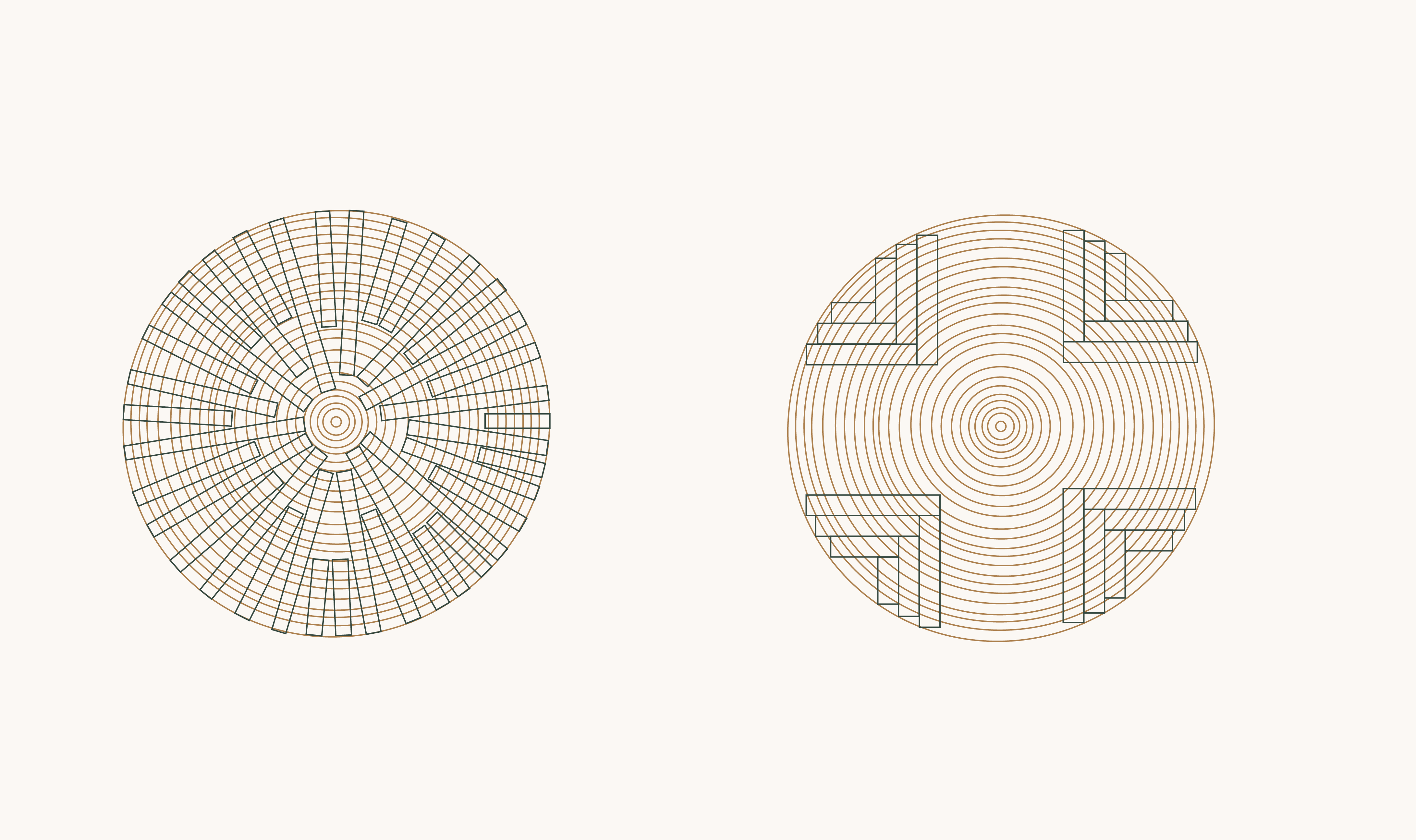

The most common method is flat sawing, a.k.a. plain or tangential sawing (above right).

Flat sawn logs are sliced with the growth rings generally less than 45 degrees to the plank’s face.

Most floorboards sawn in this manner will display familiar grain patterns featuring arches, known as ‘cathedral’ or ‘flame’ grain. There will also be planks with the characteristics of rift and quarter sawn oak within flat sawn oak, where the cuts near the centre of the log intersect the growth rings at certain angles.

Live sawing or through-and-through sawing (above left) is another flat sawing method where parallel cuts are made throughout the length of the log. This is the most efficient and cost-effective, producing minimal waste. It utilises almost every square inch of a tree to make usable boards and can also produce the widest planks planks.

Live sawn planks display full range of the log’s characteristics, from the tight-grained heartwood at the centre of the log, to the outer sapwood.

Rift Sawing and Quarter Sawn Oak

Rift and quarter sawn oak flooring is visually appealing with minimal grain variation. Floorboards sawn this way are also more dimensionally stable; however, it is more costly and wasteful to produce. There is a lot of confusion about the industry terminology used when describing this material, but the below should clarify what we mean when we talk about rift sawn oak and quarter sawn oak.

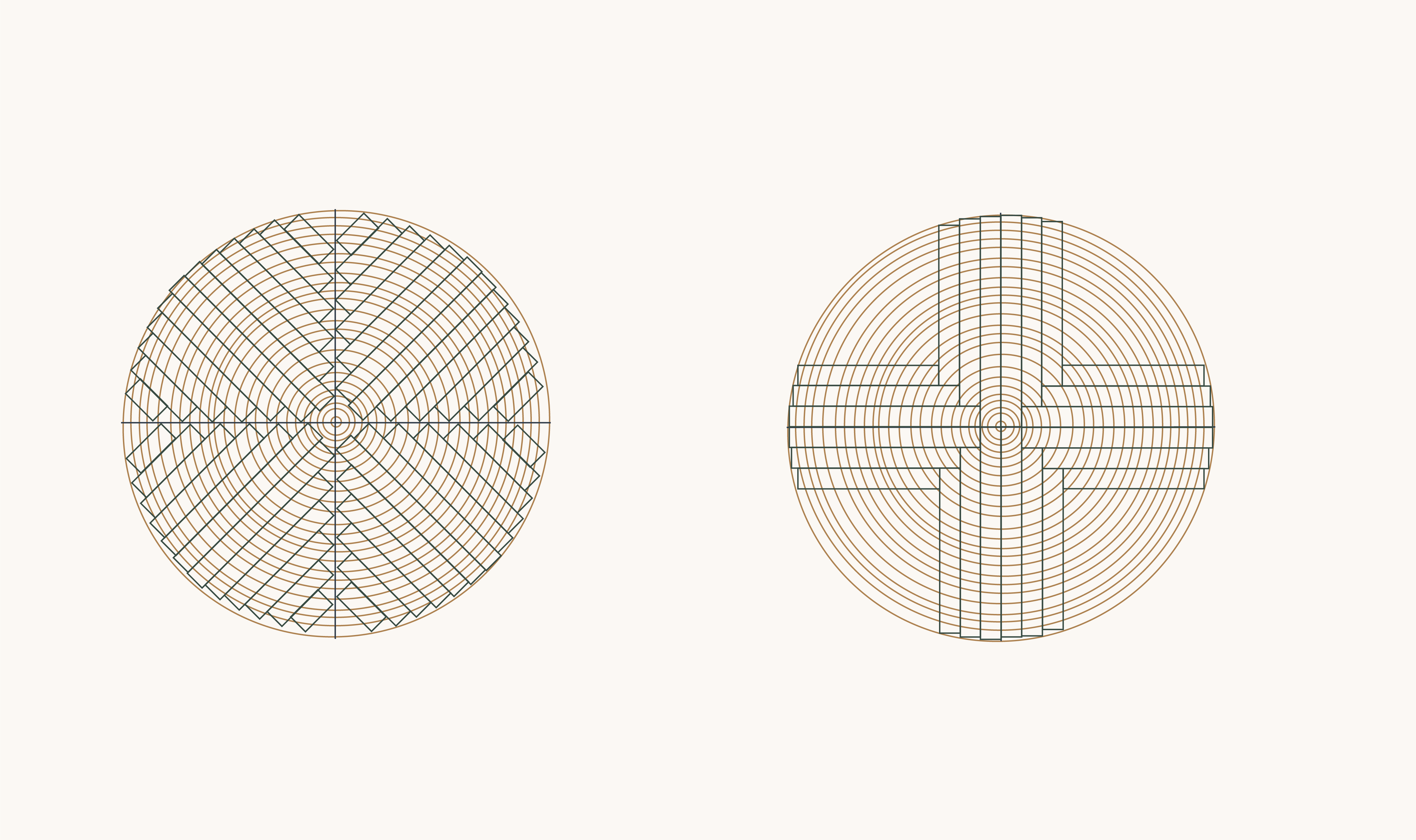

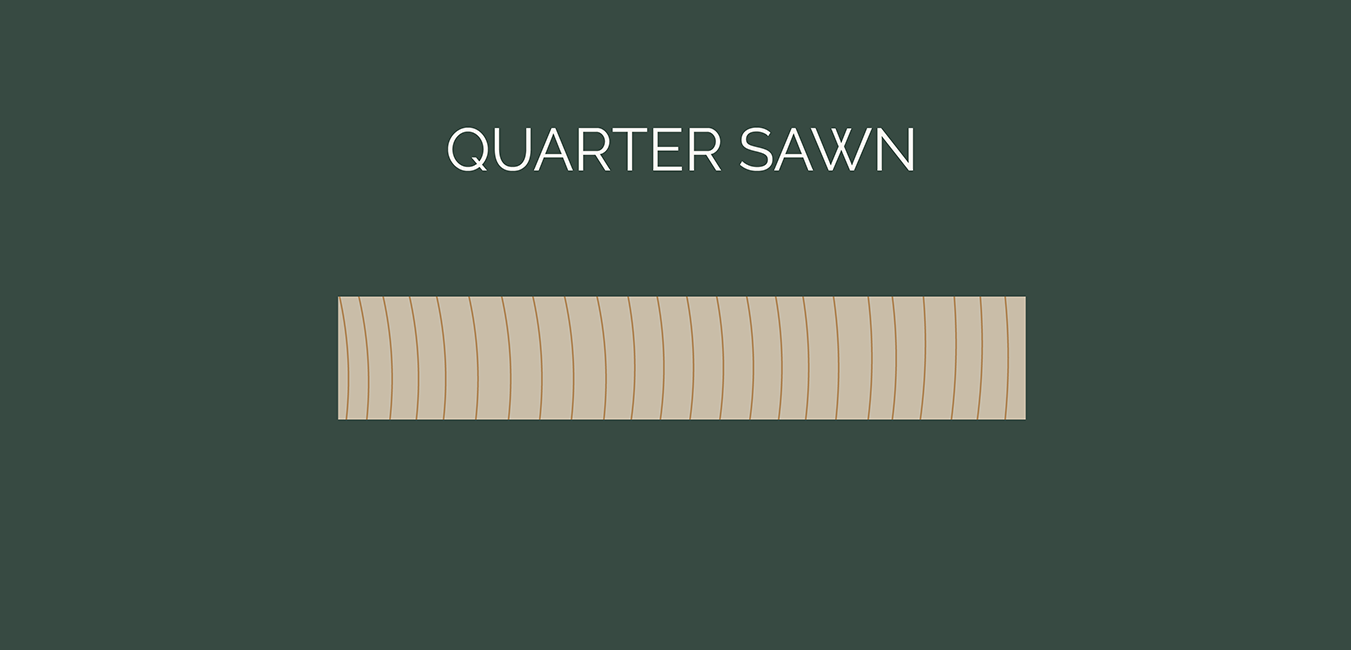

Quarter Sawing

Sawmills produce quarter sawn oak by cutting the logs into quarters and then sawing them to specifically intersect the annual growth rings so that they are between 60 and 90 degrees to the face of the plank (end grain largely perpendicular to plank’s face).

This method creates a tighter vertical grain pattern, with straight grain on the plank’s faces, and ‘cathedral’ grain on the sides.

Quarter Sawn also features dramatic figuring, known as medullary ray flecking. And it’s worth noting that this sawing method usually yields narrower planks because the log is initially quartered.

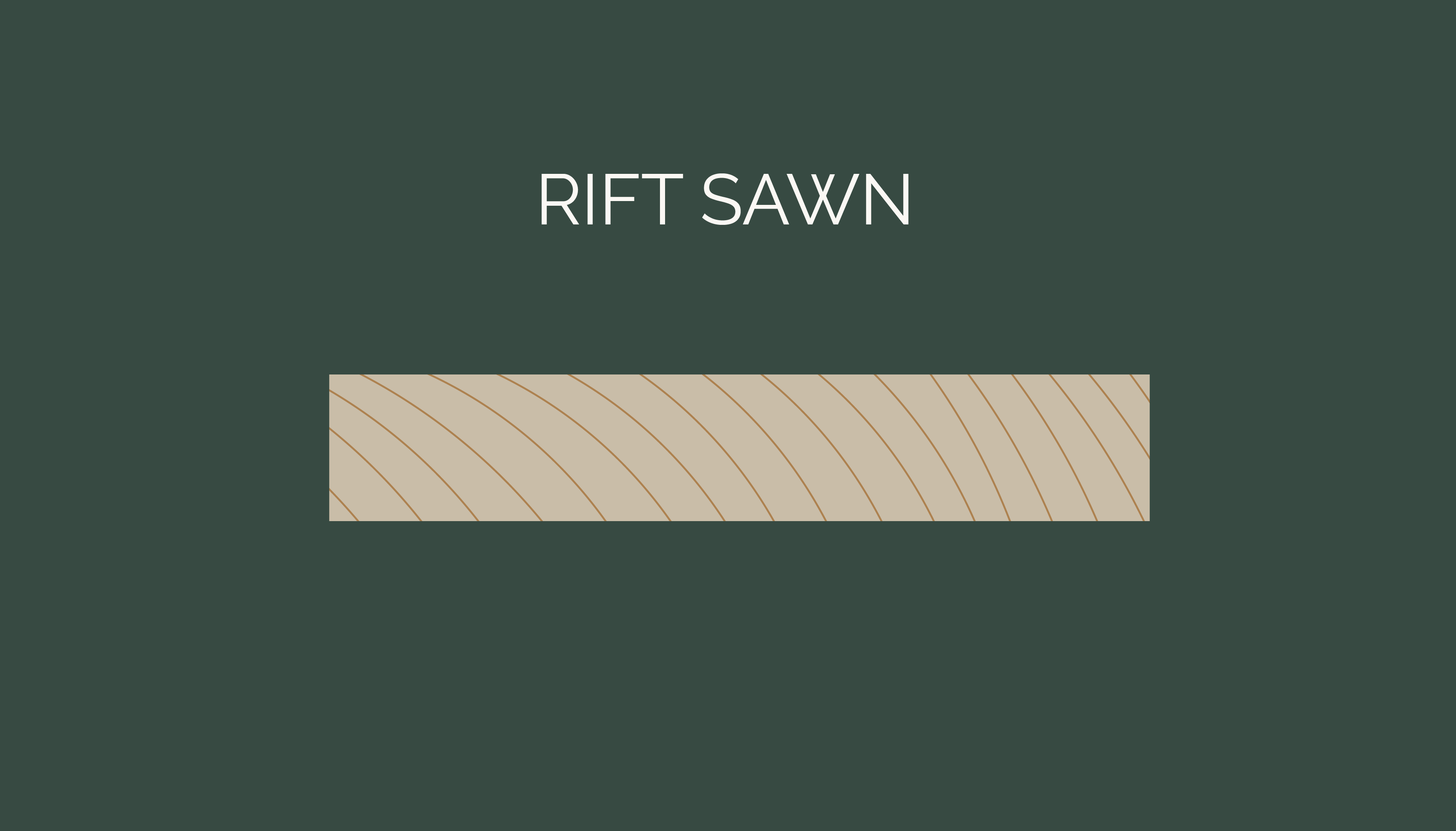

Rift Sawing

Rift sawn lumber is cut so that the annual growth rings are between 30-60 degrees to the face of the plank, with 45 degrees being optimum angle (look for diagonal end grain). This produces very consistent, straight grain on both the faces and sides of the plank, which makes it very stable.

The confusing bit: sawmills often refer to rift sawing when talking about the radial sawing process which produces only quarter sawn oak (above left).

Cutting a log in this way leaves large triangles of waste from between each board. Rift sawn lumber often gets selected out from quarter sawn wood (above right) to reduce the wastage. This makes rift sawing the most costly method, producing the most expensive planks.

Rift sawn wood sold in the timber trade is usually classified by the wood’s grain orientation illustrated below.

An example: imagine you want to make an oak table leg with very straight, unifom grain on all four sides of it. To achieve this, the ideal material would be rift sawn oak.

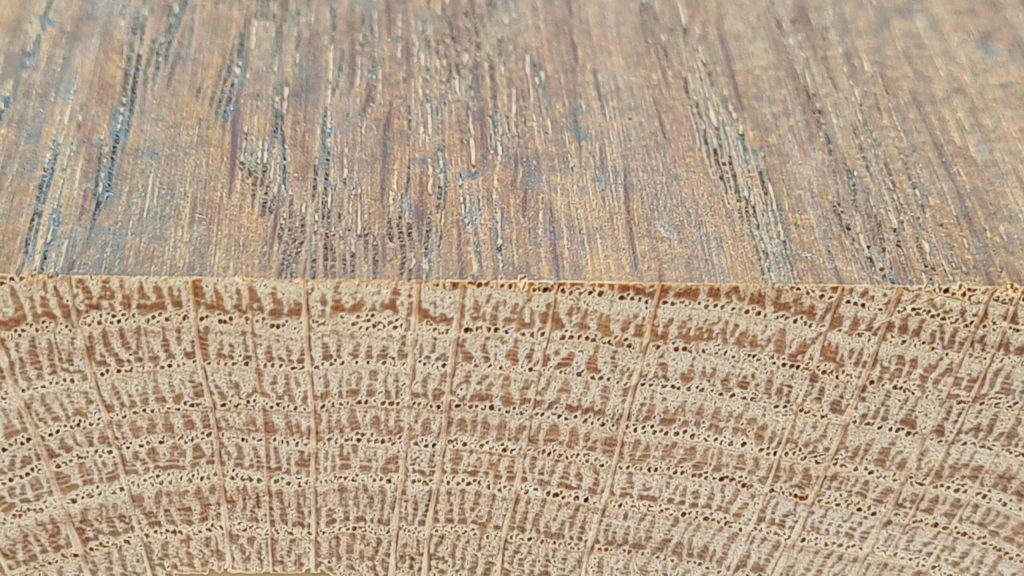

Figuring: Medullary Rays

Oak trees also produce ray cells that extend outwards from the centre of the trunk; these are used by the tree to transport sap and store plant sugars. When Oak is sawn in a certain way, these medullary rays become a striking feature, displaying as prominent shiny flecks.

These beautiful medullary rays are found in flat sawn planks of all grades, however, quarter sawn oak displays a large amount of these cells. This is due to the specific angle of the cuts used in this sawing method.

Oak’s Grain Structure

As the tree grows, it creates long, narrow vessels; these cells are like pipelines transporting water and nutrients along the length of the trunk and branches. When you view a piece of oak from the end grain, these vessels appear as holes in the wood- these are commonly called pores. They give the wood its grain structure.

Oak is described as medium to coarse grained (or open-grained) in texture, meaning it’s made up of large open pores creating its distinctive grain.

The wood is decribed as ‘ring porous,’ with its structure reflecting the differences in cell growth during the changing seasons. These alternating areas are obvious in oak, showing as prominent radial growth rings.

Seasonal Growth

The trees will grow at varying rates and create different cells at different times of the year. This is due to the contrasting environments provided by temperate regions where they grow.

Looking at a cross-section of an oak log you can easily see the earlywood, where it has grown quickly and large pores have been created, and denser latewood fibres created when the tree grew more slowly.

What To Look For: Grain Patterns of High-Quality Oak Flooring

Beauty is subjective, but we believe high-quality flooring should display defined flowing grain patterns with a clear direction and natural variation, creating interesting organic shapes.

Want to Learn More About Oak Flooring?

Come and experience our high-quality timber flooring first hand at our Bristol showroom.